Certification positions the company as the only DNV-approved WAAM manufacturer in Europe, unlocking new opportunities for offshore, maritime, and subsea sectors

Harry Thompson - Technical Director at DEEP Manufacturing; Sacha Hussey - Project Engineer at DEEP Manufacturing; Dr Eva Junghans - Senior Principal Engineer, Lead of Practice Materials & Welding, Additive Manufacturing, DNV Maritime; and Thorsten Lohmann - Head of Materials & Welding at DNV Maritime

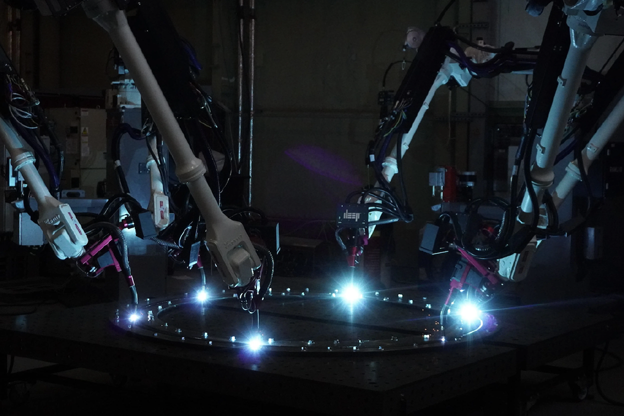

DEEP Manufacturing Ltd, the large-scale additive manufacturing specialist launched earlier this year, has been granted full Approval of Manufacture (AoM) from classification society DNV, making it one of only a handful of manufacturers worldwide - and the only one in Europe - to fully meet DNV’s standard for Wire Arc Additive Manufacturing (WAAM).

This milestone builds on DEEP Manufacturing’s earlier Approval in Principle (AiP) from DNV Maritime and represents a critical step in validating WAAM as a safe, reliable, and commercially viable process for mission-critical applications. The Approval covers the use of WAAM for the production of pressure vessels, pressure vessels for human occupancy, and hull structures and equipment, underscoring DEEP Manufacturing’s ability to meet the most rigorous international standards.

DNV’s AoM programme is designed to verify a manufacturer’s ability to consistently produce materials and products to given specifications and in accordance with rule requirements. Peter Richards, CEO of DEEP Manufacturing, described the certification as a “landmark achievement” for both the company and for the wider adoption of WAAM.

He added: “Being one of the few manufacturers globally, and the only in Europe, to secure this level of approval demonstrates both the maturity of our technology and the trust placed in our processes. It proves that DEEP Manufacturing is ready to deliver large, safety-critical WAAM components to the highest standards.”

Thorsten Lohmann, Head of Materials & Welding at DNV Maritime, added:

“We are very pleased to award this new AoM for WAAM to DEEP Manufacturing. This recognition is built on a productive and longstanding cooperation, and we thank DEEP Manufacturing for their trust and choosing DNV as their classification partner.

“WAAM and Additive Manufacturing (AM) techniques have made great strides over the past several years, creating new potential efficiencies in logistics and supply chains, as well as maintenance and repair. At DNV we are committed to enabling these technologies through our evolving AM rules, to ensure that we build this segment on a foundation of expert and independent safety and quality standards.”

By demonstrating that Wire Arc Additive Manufacturing can meet the most stringent international safety and quality benchmarks, DEEP Manufacturing is helping accelerate the shift toward more flexible, cost-efficient, and sustainable production methods. The certification gives operators across offshore, maritime, and subsea sectors the confidence to deploy large-scale WAAM components in mission-critical environments where reliability is paramount.

Peter continued:

“We are entering a new era of manufacturing for the offshore, maritime, and energy industries, and our focus is on helping customers embrace innovation and build more adaptable, resilient operations. This milestone marks a tipping point for the industry - the moment to fully unlock the advantages that Additive Manufacturing can deliver.”

KeyFacts Energy Industry Directory: DNV

KEYFACT Energy

KEYFACT Energy