Porthos has taken a final investment decision to develop the first major CO2 transport and storage system in the Netherlands. In 2024 construction will begin in Rotterdam, with the Porthos system expected to be operational by 2026. The Porthos infrastructure requires an investment of €1.3 billion. With the final investment decision reached, Porthos will now award contracts required to realise the project.

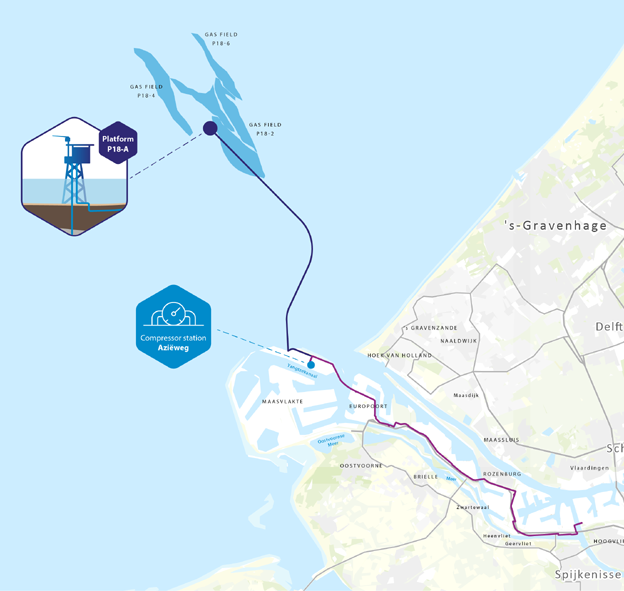

Porthos is a joint venture of EBN, Gasunie, and the Port of Rotterdam Authority. Porthos will provide transport and storage services to several companies in the port of Rotterdam, including Air Liquide, Air Products, ExxonMobil, and Shell. These companies will invest in their own capture installations to supply CO2 to Porthos. Porthos will transport the CO2 through the port of Rotterdam to depleted gas fields in the North Sea, approximately 20 km off the coast, where it will be permanently stored at a depth of 3 to 4 km under the seabed. Porthos plans to store about 2.5 Mton per year for 15 years, totalling around 37 Mton. With that, Porthos has contracted its full storage capacity. The onshore transport system under construction allows for future CO2 storage projects.

Hans Meeuwsen, Porthos director:

“CO2 storage is crucial if we want to achieve the climate goals in the Netherlands. This investment decision is an important starting point for future developments in CO2 storage in the Netherlands.”

Carbon Capture and Storage (CCS) is a cost-effective way to keep large amounts of CO2 emissions out of the atmosphere in the short term. It is therefore an important pillar of the Dutch government’s climate policy. Thanks to Porthos, the Rotterdam port industry will soon emit about 10% less CO2. At the same time, the industry is working on the transition to processes based on renewable energy and raw materials.

To realise the project, Porthos partners with TAQA Energy, the present operator of the P18 gas fields, and specialised contractors and suppliers such as Denys N.V., Allseas, LMR Drilling GmbH, Mannesmann Grossrohr GmbH, Corinth Pipeworks, Equans, Ensco Offshore, Van der Ven and Bonatti. Together, under Porthos’ direction, they will deliver the required infrastructure.

The European Union recognised Porthos as an important project in meeting climate targets, declaring Porthos a Project of Common Interest and awarded €102 million in subsidy for it.

Porthos project

Porthos is developing a project in which CO2 from industry in the Port of Rotterdam is transported and stored in empty gas fields beneath the North Sea.

The CO2 that will be transported and stored by Porthos, will be captured by various companies. The companies will supply their CO2 to a collective pipeline that runs through the Rotterdam port area. The CO2 will then be pressurised in a compressor station.

The CO2 will be transported through an offshore pipeline to a platform in the North Sea, approximately 20 km off the coast. From this platform, the CO2 will be pumped in an empty gas field. The empty gas fields are situated in a sealed reservoir of porous sandstone, more than 3 km beneath the North Sea.

Porthos will store around 37 Mton CO2, approximately 2.5 Mton CO2 per year for 15 years.

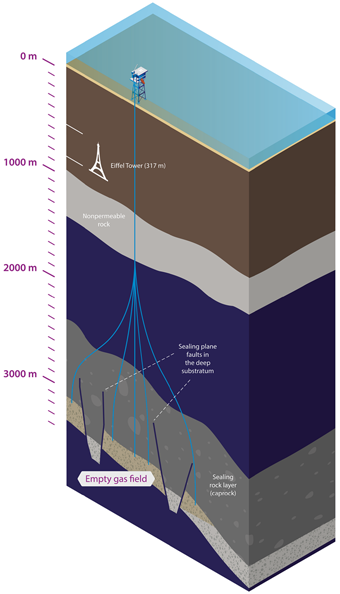

Storage

The collected CO2 is stored in the pores of the sandstone substratum, which used to contain natural gas. For millions of years, this gas was hermetically trapped under high pressure between a nonpermeable layer of caprock and sealing plane faults. The local pressure in this field, which gradually decreased during gas extraction, will once again rise as a result of CO2 injection. The reservoir will be consistently monitored and checked to ensure that local pressure never exceeds the values recorded when gas extraction first started.

The CO2 from the pipeline will be injected into the depleted gas field under P18-A via a well. This well is a metal casing that is anchored to the rock all the way down to the reservoir in the substratum. To make the existing facility suited for CO2 injection, the well will be fitted with a new inner tube. The wells will also have monitoring equipment that is used to check the local pressure and temperature during CO2 injection. Once CO2 injection has been completed – when the reservoir is full and at the correct ultimate pressure – the wells will be sealed with plugs.

KeyFacts Energy: Carbon Capture news

KEYFACT Energy

KEYFACT Energy