By Kathryn Porter, Watt-Logic

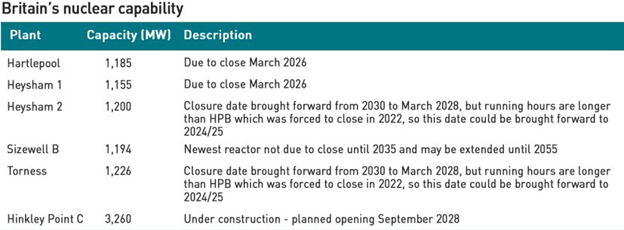

Last week came the welcome news that EDF will extend the lives of its Heysham 1 and Hartlepool nuclear reactors by a further two years to March 2026. The company had hinted at a possible extension back in September but the subsequent inclusion of nuclear power in the windfall tax put the decision in doubt. Having secured contracts in this year’s T-1 capacity auction, the plants were likely to remain open until September 2024, but that could potentially have been achieved by simply managing the fuel.

This announcement secures their lives for a further two years provided that the results of regular graphite inspections remain positive and the Office for Nuclear Regulation agrees. Two previous reviews resulted in the reactors having their lives extended by 10 years. The estimated closure dates for Torness and Heysham 2 remain unchanged at March 2028 however both of these reactors have run for longer than Hinkley Point B which was forced to close in 2022 following the discovery of cracking in its graphite cores.

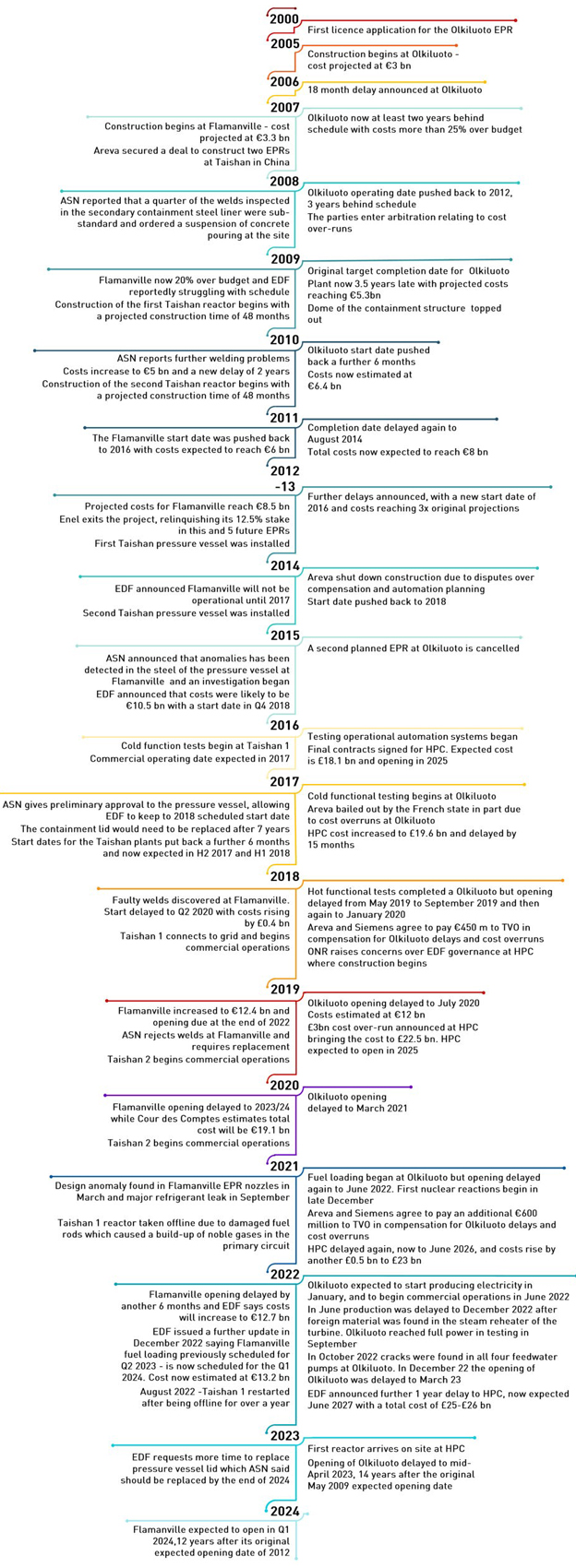

However, EDF has also announced there may be further delays to its new British reactor at Hinkley Point whose opening could be pushed back to September 2028. That means that by the time it opens, there will only be one nuclear power station – Sizewell B – operating in the UK, posing real risks to security of supply as this decade progreses. The cost of Hinkley Point C has also ballooned from its initial estimate of £18.1 billion to £32 billion.

Meanwhile EDF’s first EPR (European Pressurised Water Reactor) in Europe, Olkiluoto 3, is limping towards an opening which keeps being incrementally put back. The latest date is now 17 April. The plant had been expected to open in June last year, but this was put back after material was found to have detached from the steam guide plates and entered the steam reheater of the turbine. Then in October, cracking was found in all four feedwater pumps at the reactor, pushing the expected opening date to December. When December came opening was delayed to February when it was pushed to March, and then to April.

The news at the flagship plant at Flamanville is no better. In December EDF provided an update saying that fuel loading, which had previously been scheduled for Q2 2023 will now take place in Q1 2024. It also announced a cost increase to €13.2 billion, up from the previous estimate in 2022 of €12.7 billion. The company is still in the process of repairing 122 faulty welds.

This brings the start date to within months of the deadline of the end of 2024 for replacing the pressure vessel lid, mandated by regulator Autorité de Sûreté Nucléaire (“ASN”) after the discovery of excess carbon in the steel. In 2018 when ASN made the stipulation, this was expected to be the time of the reactor’s first re-fuelling. EDF has requested an extension of the deadline to avoid having to shut down the reactor after just a few months of operation, but there is no guarantee that the plant will open on Q1 2024. ASN may just require EDF to replace the lid before opening, rather than moving it to the date of the first re-fuelling as requested by EDF.

Stress corrosion problems still not resolved

In October 2021, EDF discovered stress corrosion cracking during the ten-yearly inspection of the Civaux 1 reactor. This turned out to be a generic problem on N4 and P4 reactors which led to the closure of 12 reactors during the winter of 2021-2022. By November last year, 115 welds and 230 samples had been assessed. The investigations found that the 16 newest reactors were more prone to the phenomenon due to the sinuous design of their emergency cooling pipes, although cracks could also be caused by welding and other defects.

The inspection and repair work is challenging – according to Bloomberg each weld takes at least three days to complete, with workers often on their knees or backs to reach for the correct angle. Even in radiation suits, health regulations limit work in that environment to a maximum 40 hours a year. 100 specialist welders have been brought in from North America to work alongside 500 local metal workers and engineers. Tools have had to be adapted for working in confined spaces, with welders using mirrors to work on piping located close to walls.

“These are complex situations, in a noisy and radioactive environment…Workers can sometimes only hold their position for just a few minutes before they need to be replaced,”

– Laurent Marquis, a manager at Altrad Group-Endel which is coordinating the repairs for EDF at Penly

Of the dozen reactors where pipes were cut for checks, EDF found no sign of cracking in three of them, while two had cracks caused by welding defects where tiny portions of metal had been insufficiently melted. However, in the majority, stress corrosion was found resulting in cracks as deep as 6 millimeters. EDF plans to replace emergency cooling system piping in seven reactors as a preventative measure during planned outages of 160 days, starting this spring, to avoid doing weeks of checks only to find the pipes need replacing anyway.

Last week, ASN announced that EDF had detected a “non-negligible” defects in welds on emergency pipes in two reactors: Penly 2 and Cattenom 3 where thermal fatigue cracks have been found during inspection. This discovery comes two days after the revelation of a crack of a size never seen before in the Penly 1 reactor. The crack at Penly 1 extends over 155 mm, or about a quarter of the circumference of the pipe, and its maximum depth is 23 mm, for a pipe thickness of 27 mm.

This particular pipe had not been considered by EDF as not susceptible to stress corrosion cracking due to its geometry. However, this weld underwent a double repair during the reactor’s construction, which could have altered its mechanical properties and the internal stresses of the metal. However, the discovery of this crack means that this piping must now be considered vulnerable, and EDF has been required to update its approach to the stress corrosion issues as a result. The company is now checking welds on other emergency cooling lines that have been repaired in the past.

ASN says that while this crack is concerning, the safety system for the nuclear reactor is designed so that it could tolerate a rupture of one of these coolant pipes. Some of the corroded pipes at the Penly and Cattenom have already been replaced, but it is not clear if that includes the severely cracked pipe.

The crack at Penly 2 is 57 mm long and represents less than 10% of the circumference, with a maximum depth of 12 mm, while the crack at Cattenom 3 is 165 mm long, about a quarter of the circumference, with a maximum depth of 4 mm.

The discovery of these new defects could disrupt the maintenance schedule of French nuclear fleet. As a result of the stress corrosion issue, EDF has to inspect 200 welds across its reactors, which could lead to further outages and increased uncertainty over nuclear output during 2023 after severe disruption last year. As these new cracks are due to thermal fatigue rather than stress corrosion EDF will have to adapt its maintenance program to include thermal fatigue checks.

“The discovery of this materially worse-than-expected defect is likely to lead to more rigorous quality control and potentially longer outages…If this were to be the case, we would expect the French power-price outlook to increase,”

– Vincent Ayral, analyst at JPMorgan Chase

Output from the French nuclear fleet fell from 361 TWh in 2021 to 279 TWh last year. EDF estimates it will recover to 300-330 TWh in 2023, but that still means France could require imports for a significant portion of the year, and the identification of new cracks, or delays in the repairs – France is currently experiencing strikes including among nuclear workers – could see production fall below estimated levels. So far in 2023 output has been lower than last year: 30.8 TWh versus 25.3 TWh for January and 59.6 TWh versus 64.8 TWh in February. Although some of the affected reactors have re-opened, others have seen their closures extended.

- Cattenom 1 (1.3 GW) re-opened on 5 February 2023

- Chooz 2 (1.5 GW) re-opened on 8 February 2023

- Cattenom 3 (1.3 GW) will be closed until 26 March 2023

- Civaux 2 (1.5 GW) will be offline until 20 March 2023

- Chooz 1 (1.5 GW) will remain closed until 4 April 2023

- Flamanville 1 (1.3 GW) will be offline until 2 June 2023

- Golfech 1 (1.3 GW) will remain closed until 11 June 2023

- Penly 1 (1.3 GW) will be closed until 2 May 2023

- Penly 2 (1.3 GW) will be offline until 11 June 2023

EDF is still trying to understand the speed at which cracks progress once they appear. This means it faces tighter and more frequent monitoring of its reactors, and the replacement of the piping in the seven reactors planned for this year is unlikely to be the end of the story – EDF expects that it will continue to encounter issues relating to stress corrosion into 2024 and 2025.

Beyond this, the French reactors are aging – most were built from the late 70s to the mid-90s, and now require longer down time for maintenance and repairs. ASN has previously warned that the stress corrosion issues may not be the last problems uncovered. Countries such as Britain which have long relied on French electricity imports should take note.

Troubled history of the EPR

Original article l KeyFacts Energy Industry Directory: Watt-Logic

KEYFACT Energy

KEYFACT Energy