By Jason Smith, Global Director for Geo-data Analysis and Geoconsulting at Fugro

Wind farm developers can achieve significant cost savings on foundation design and installation scopes by carefully planning the data acquisition and analysis stage. Jason Smith, one of Fugro's marine site characterisation experts, explains key strategies for meeting today’s cost and schedule challenges.

Engage a Geo-data expert early on

Reach out to a reputable Geo-data provider at the outset, even before being awarded a lease, to gain an overview of the conditions at your wind farm site. Understanding site conditions is vital for creating an early-stage ground model, planning site investigations that identify ground risks and constraints, and evaluating the feasibility of foundation concepts and potential construction costs of your proposed development.

Choose your expert wisely. Do they have both local knowledge of the ground conditions and global experience in offshore development? How do they analyse and identify constraints and uncertainties before planning field acquisition programmes? Can they evaluate various Geo-data and understand the engineering implications for foundation designs?

Fugro Synergy supporting the Borssele project in the Netherlands

Obtain early insights

Initial desktop studies start the process of unlocking insights about the expected ground conditions at your development site. Geo-data used for these studies often includes public domain and client-specific information, plus local knowledge and consulting experience.

These studies provide early indications of existing environmental, geohazard and engineering constraints, and highlight any data gaps and site uncertainties. Use this knowledge to design a targeted and fit-for-purpose acquisition programme that provides the engineering-scale Geo-data necessary to increase site clarity, narrow the range of uncertainty, avoid additional acquisition time, and reduce project risk.

Process data quickly

Select a data acquisition provider that uses state-of-the-art technology to acquire and transmit high-resolution data from the field in near real time to specialist consultants and stakeholders onshore. This will shorten your timelines for data processing, integration, analysis, and reporting.

Data transmission to shore will also reduce HSSE exposure by relocating the quality assurance and control process from offshore to onshore. When combined with computer-aided machine-learning interpretation tools, the time it takes to receive your reports is accelerated by at least several weeks over a nominal 1 GW survey programme and by months for areas with complex site conditions.

For example, Fugro’s integrated Gaia.Live™ platform enables you and your development teams to log in remotely and track a full geospatial overview of field acquisition activities. With fast access to the latest quality controlled Geo-data, you can make quicker decisions about field investigation results, accelerate understanding of site conditions, and analyse different development scenarios that improve the operational timelines.

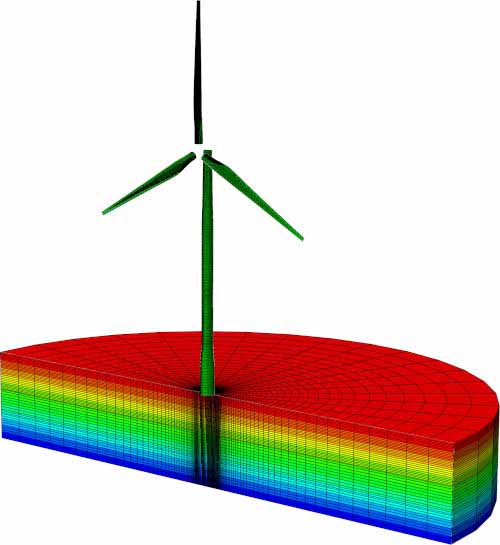

Finite element model of wind turbine, monopile and soil for seismic analysis

Apply a consultant mindset to laboratory testing

Wind farm developments often default to specific laboratory testing programmes to characterise soil properties for each recovered sample, but this rigid approach is inefficient. Consultancy-led programmes can optimise the type, depth and frequency of tests required to address foundation considerations.

For example, if the early tests indicate little variability in the soil conditions and this is supported by the geological model, the number of tests can be reduced to accelerate progress and drive down costs. If the geological soil units are variable and contain deposits susceptible to cyclic degradation, more tests will be needed to define the soil bearing capacity for the foundation design loads.

Use numerical modelling

When site-specific test results are incorporated into a traditional 1D model, the required foundation dimensions tend to be overestimated, adding to construction costs and installation time.

However, incorporating them into a 3D numerical model produces more reliable predictions of installed foundation performance under loading conditions such as wind, waves and currents. For example, if the soil-structure interaction analysis from the numerical model indicates that a monopile can be shortened by 5 m and still satisfy performance requirements, this could reduce the costs for each pile by more than USD 100,000 in steel alone.

Our experts perform numerical modelling on a variety of foundation types, including monopiles, gravity-based foundations, and anchors for floating wind. In earthquake-prone areas, 3D digital twins are used to predict how the soil and proposed foundations will respond to seismic-induced shaking that could cause performance issues, reduce fatigue life or lead to structural failure.

In conclusion…

The largest influence on the outcome of any offshore wind farm project occurs in the initial stages, where the most cost-efficient concept is determined, so early engagement with Geo-data experts is key to meeting accelerated wind farm timelines.

Working with a team of multidisciplinary consultants early on and throughout the phases of acquisition, laboratory testing and foundation design performance analysis can save millions of dollars in construction costs, installation costs and lost revenue caused by operational delays.

DID YOU KNOW?

- Design, production and installation of foundations account for up to 34% of a wind farm’s development budget

- Around 75% of offshore wind farms use monopile foundations – massive cylindrical steel tube structures driven or drilled into the seabed to support the wind turbines’ static and dynamic loads

- Modern monopiles can be more than 90 m long, almost 12 m in diameter and weigh between 2000 t and 3000 t

KeyFacts Energy Industry Directory: Fugro

KEYFACT Energy

KEYFACT Energy